I didn’t see many motorcycles when I paid a brief visit to Dubai a few years ago. The streets were full of Toyota Landcruisers, growling supercars and Mercedes sedans with black tinted glass.

But the most populous city in the United Arab Emirates has a thriving biker scene if you know where to look, and even an annual custom show called ‘Art of Motorcycles.’

One of the key players in the local custom scene is Möto Rauch & Staub. A full-service workshop with a café and barbershop attached, it was started up by German Marco Möller. South African photographer Antonie Robertson lends a hand on the custom builds.

This 1999 Sportster is the ‘shop bike’—a quirky carbureted XL1200 that Marco (below left) and Antonie (below right) can use for running errands.

“The idea was to build a small, fun scoot that could be used as the shop daily,” says Marco. “We wanted to trim off all the proverbial Harley fat that these bikes are known for. Because the first thing that happens usually is new owners ‘upgrade’ the bike with chrome covers and cheap indicators!”

The XL1200 was stripped down to the essentials, and the ideas started flowing. This was not to be a big budget build, so a little inventiveness was called for.

And since Dubai was in lockdown during the build and Marco and Antonie had time on their hands, they decided to do as much fabrication as possible—rather than ordering in off-the-shelf aftermarket parts that could take weeks to arrive.

They located and installed a set of Sportster Forty-Eight forks, but that immediately created an extra problem. “The hardest part of the build was fitting a 16-inch aluminum disc wheel—popular with the older Sportster models—into the forks,” says Antonie. But the wheel was necessary to match its twin at the back.

So the hub was machined down, and fettled so that the brake rotor matched the caliper. “When that all lined up, I had to design a new axle and spacer bushes to placed the wheel square in the center of the new forks,” Antonie reveals.

“Now, even though it’s a 1200, the scoot has a tiny stance and feels very unassuming. But put the little dragon into a corner and you’ll love the 16-inch front wheel.”

The other big fabrication job was the new headlight, which is a repurposed old spotlight from a Jeep, with new high- and low-beam internals. Multiple cut aluminum shapes were hand-hammered, welded up, filed down and hand polished, to create a single unit that looks like it was sandcast back in the day.

“This was a major task with all the facets we had to consider, and it’s my favorite part of the build by far,” says Marco.

The satin black powdercoated bars are a ‘Bootlegger’ bend from TC Bros, and kitted out with Lowbrow grips, Japanese Posh switchgear, and a master cylinder and clutch control that were lying around the shop—both from KustomTech.

The throttle is repurposed from an old Japanese bike, and there’s no speedo on the bars. Instead, a tiny MMB unit sits down low, below the tank on the left hand side.

The tank was literally a rust bucket found on a shelf in the workshop. Given the classic peanut shape, it was a good match—so the boys cleaned it up, flushed out the inside, and made it fit.

“We wanted it to be a one-seater. We wanted to keep the shocks too: we did play around with the idea of a hardtail, but considering it would be a run-around, we decided to go more for comfort.”

Ideas were kicked around for a rear fender treatment, and Marco and Antonie eventually took inspiration from the Japanese approach. There’s a bobbed and kicked-up fender, a recessed indicator mount and a small hand-shaped aluminum cover that completes the frame for a harmonious line.

The taillight assembly, now with LEDs fitted, was made from a salvaged exhaust. It’s quite an aggressive look, but also follows the fender line. “We wanted the rear line to be smooth, but still give the tail section an aggressive stance with the Duro Median tires we decided to fit,” says Marco. The shocks are from Progressive Suspension, and another salvage find.

The engine has been treated to a Screamin’ Eagle slide carb and ignition system, a complete new custom exhaust system, and a chain drive conversion kit for a more classic look.

Less visible is the new wiring loom, centered on a Motogadget m.unit control box. Much of the wiring now runs inside the frame, with a lithium battery and the bulkier electronics now hidden under the seat on the left side.

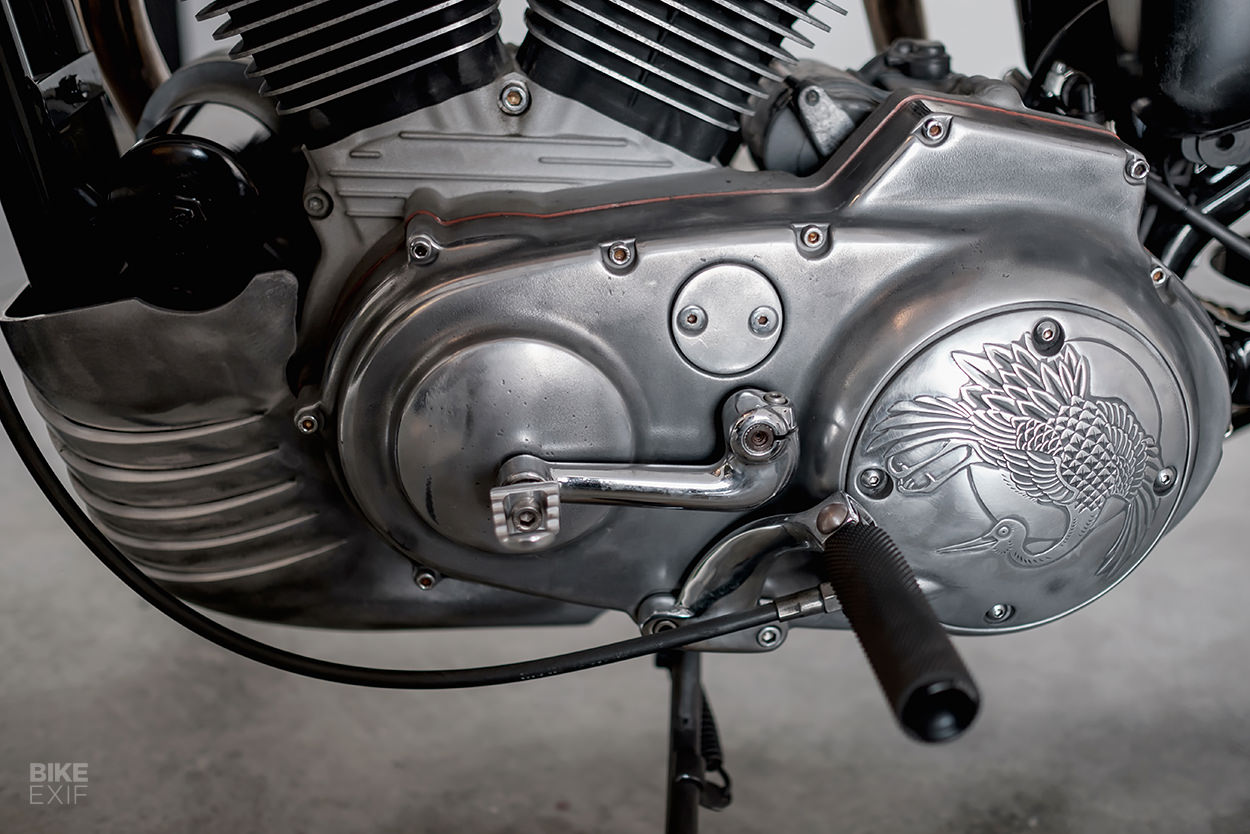

Hand made (and often intricately engraved) details abound all over this Sporty, from the trimmed and polished covers to the aluminum skid plate and custom air intake filter. There are even Japanese coins discreetly embedded around the machine, in obscure places such as on the brake calipers.

“This bike was about figuring out what we wanted to build, and what we wanted to come out of Möto—now and in the future,” says Antonie.

“We didn’t have a big budget for expensive, off the shelf parts. We wanted to make everything ourselves, or use what we literally had lying around. And when we bought parts, they were always altered to fit.”

Like they say, necessity is the mother of invention. This Sportster might be cobbled together from found parts, but we’d take it over your typical Sturgis exhibition V-twin any day.

Möto Rauch & Staub Instagram | Images by Nihed Baouab

from Bike EXIF https://ift.tt/38TW8eV

No comments:

Post a Comment