Most custom builders are low-volume guys. It’s often a sideline to a day job, or part of a wider operation selling parts. But there are a handful of companies that have a veritable production line, and in Europe, one of those is WalzWerk.

“We build around 50 of our ‘Schizzo’ BMWs per year, which is one bike per week,” says founder Marcus Walz. “All the bikes—the Roadster, Cafe Racer, Scrambler and Bobber—are based pretty much on the same concept.”

“But once a year we build a very special Schizzo, and this year it is this ‘Monza,’ which is inspired by old GP bikes of the 70s. Hence the reason for the nickname.”

‘Monza’ is a fantastic blend of minimalist and retro cafe racer design, based on a 1989 monolever R100 RS. And it weights just 168 kilos [370 pounds] with five liters of fuel, which is a drop of around 50 kilos on the stock R100RS.

“As always, we took the bike completely apart and rebuilt it,” says Marcus. “So it’s pretty much a brand new bike with an old title. It’s a real old bike, and not a faked retro bike. I believe this is why our production bike line is successful.”

WalzWerk have stripped all unnecessary brackets off the main frame and replaced the entire rear end, including the seat, with their classy in-house product. It’s a stepped design available as a complete kit, with no welding required.

The new frame bolts right on to the existing brackets of the main frame, and is already fitted with brackets for turn signals, a seat and the rear fender.

“After the metalwork, we powder coated the frame in-house with a special new ‘aluminized’ powder,” says Marcus. “We needed three attempts before we were satisfied with the finish.”

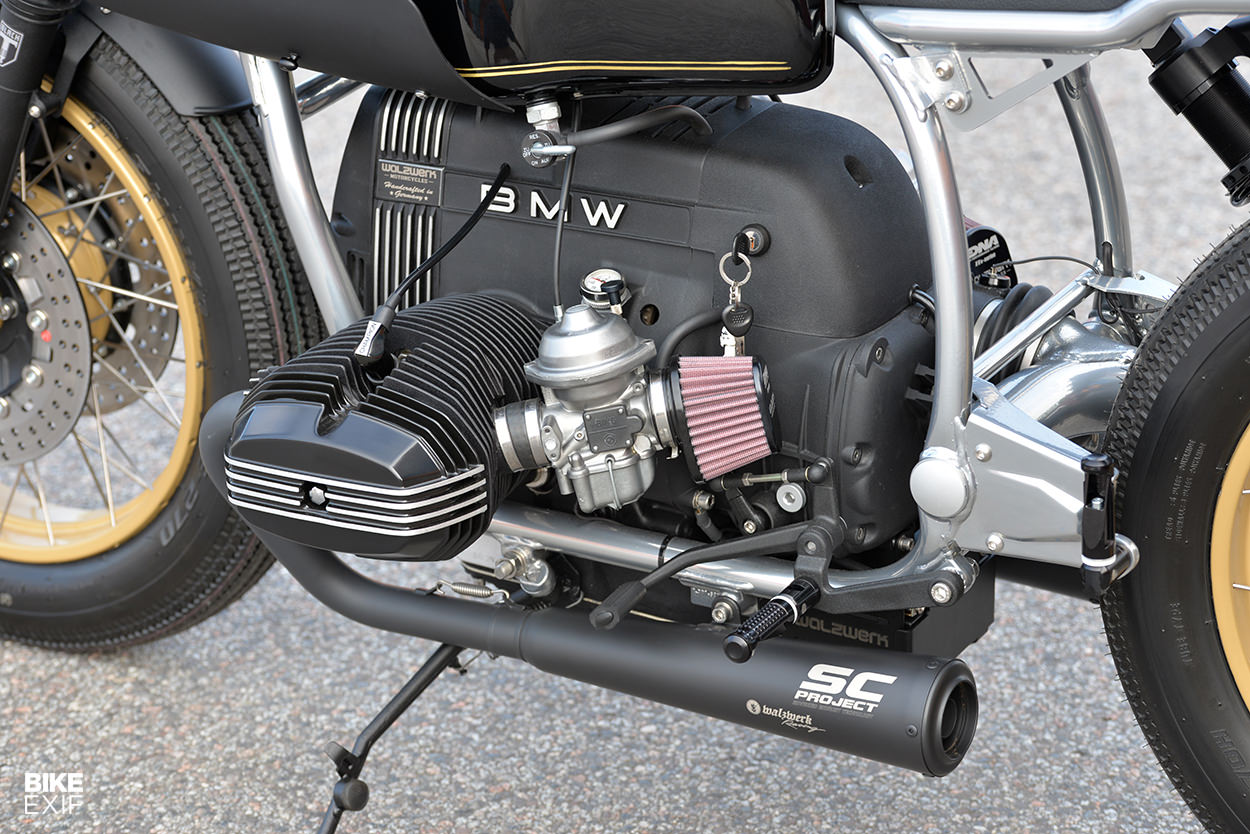

The 980cc boxer engine has been fully overhauled to give decades of more service, and has also been treated to a brand new, balanced crank and pistons, which are lightened and have slightly shorter skirts. The inlet and outlet valve sizes have been increased too.

The five-speed gearbox and rear drive have also been completely overhauled, with the housings then sandblasted and thermo-coated before being reassembled.

To boost reliability and smoothness, WalzWerk have also replaced the original ignition with a new crank-mounted Silent Hektik electronic system.

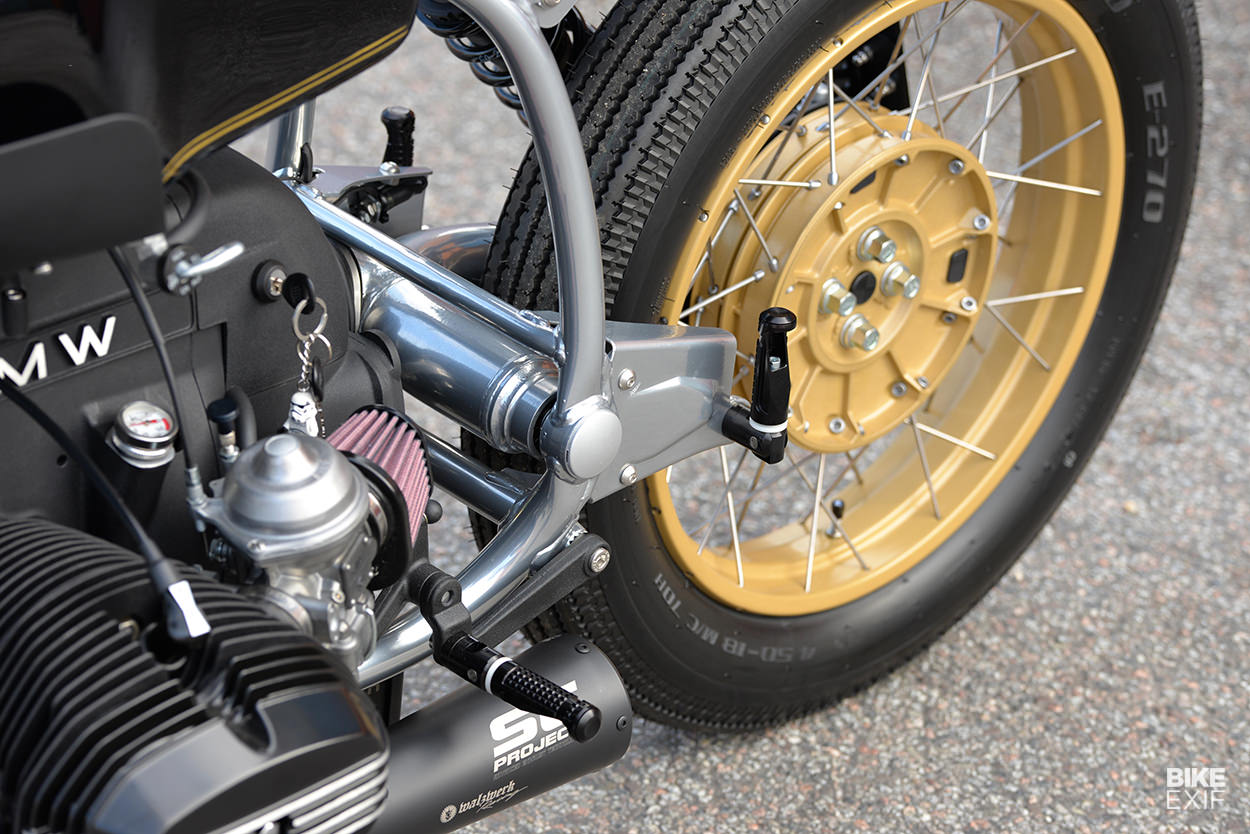

The lightweight ‘shorty’ 2-into-2 exhaust system has removable dB-killers, and is handmade out of stainless steel by SC Project in Italy and then black ceramic-coated. It’s a design exclusively made for WalzWerk, and fits all two-valve BMW airheads with 38mm header connectors.

It helps to lift power at the rear wheel to 70 hp, compared to the 60hp normally measured at the crank for a late 80s R100.

To upgrade the suspension, WalzWerk joined forces with Touratech. At the back is a fully adjustable monoshock, and the stock front end is shortened by 120mm. It’s tightened up with ‘Black-T’ progressive fork springs and new inner damper units.

The top yoke is new too, and CNC-machined out of a solid block of aluminum. The stock Brembo calipers are overhauled with upgraded floating stainless steel rotors.

The 18-inch wheel rims are lifted from a BMW R100R Paralever, with modified hubs to fit the Monolever application. They’re shod with wide-profile Shinko 270 Super Classic tires in 4.00×18 front and 4.50×18 on the rear. The rims and hubs are powder coated in a ‘BBS’-style gold metallic, inspired by classic BBS racing wheels.

The black anodized racing clip-ons come from ABM, and between them is a Motogadget Tiny gauge. A Bluetooth-controlled Motogadget m.unit blue control box keeps the new wiring harness up to date.

The most unusual item is the front fairing, which plays a big part in the weight loss. It’s heavily modified racing fairing from a Yamaha TZ250 GP bike, installed via newly manufactured brackets.

“We did all this work in house,” says Marcus. “The only things we didn’t do are the paint on the fuel tank, and the saddle work.”

“The bike is fully street legal. For the pictures, we removed the rearview mirrors, which are mounted at the bar ends. Most of the parts aside from the fairing are available in our online store.”

With a little talent, anyone can build their own TÜV-approved ‘Schizzo,’ using WalzWerk’s well-designed and priced parts.

Marcus and his crew have developed the template, and very clever it is too.

WalzWerk | Facebook | Instagram

from Bike EXIF https://ift.tt/30wt1sl

No comments:

Post a Comment