The success of the Triumph Bobber has not gone unnoticed by the more savvy custom shops. It’s the fastest-selling motorcycle in the history of the British brand, but unfortunately it’s tricky to customize—because Triumph largely ‘got it right’ at the design stage.

The French outfit BAAK has just finished this 2020-spec Bonneville Bobber 1200, and it looks superb. But there’s a bigger story than just the bike. The Lyon-based workshop will open new premises in the USA next year, and this Bobber is also a platform for their rapidly expanding parts catalog.

BAAK’s Triumph cleverly takes aspects of the factory design and amps them up further, adding a vintage vibe along the way.

Their goal was to make the Triumph Bobber feel ‘more authentic,’ while adding a little of their own DNA. “Triumph did a good job,” says shop boss Julien Demauge-Bost. “The chassis and engine are great. We simply had to find the right balance to make it more ‘punchy’ and different from the one you can find at your dealership.”

The build was an in-house project, with no client brief, and became a test bed for a new a range of BAAK parts. “But then a customer saw the motorcycle while it was still being built, and fell in love with the style,” says Julien. “He decided to purchase it. It was delivered to him last Saturday.”

BAAK are onto a good thing here, because a second customer also fell in love with the project. He’s ordered a similar build, which will be ready in a few weeks.

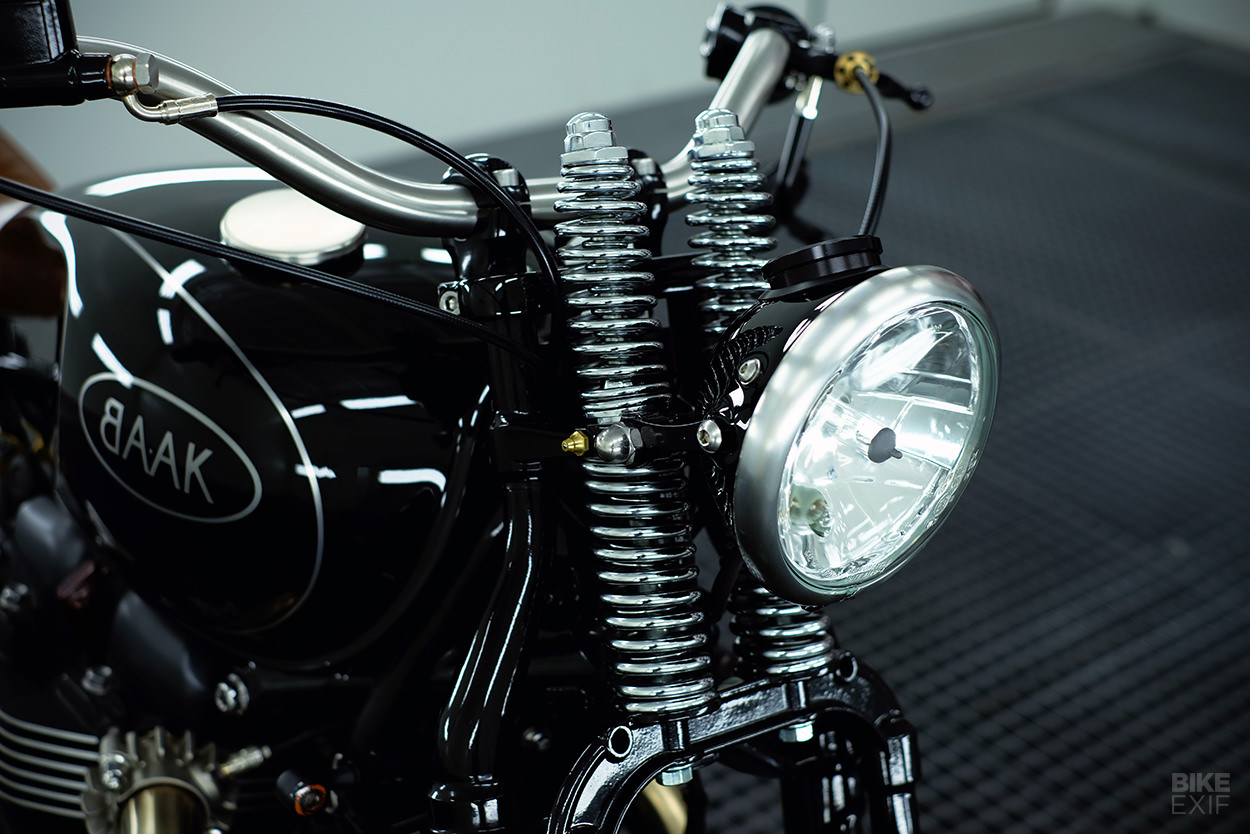

Unlike most donor bikes, tweaking a Bobber doesn’t require cutting and welding on a new rear frame—because there isn’t one. This immediately removes a major headache and allows concentration to be focused elsewhere—and in this case, that meant the front end.

BAAK selected an aftermarket springer fork—more commonly fitted to Harleys—and designed and machined a triple trees kit to make it it. They’ve also machined up a new steering column and front wheel axle, plus sundry brake parts that allowed them to keep most of the Bobber brake system.

“That was one of the biggest parts of the job,” says Julien. “And it was very tricky too: we kept the original brake caliper, and redesigned all the parts around it to make things work safely.”

The rear shock has been upgraded to a custom unit, co-designed and manufactured by Shock Factory in France. “Shock Factory is a French brand founded by a former EMC Shocks employee,” says Julien. “We’ve been working with them for years, we believe their products have the best price/quality ratio on the market. A great look, and super-easy to adjust.”

A big visual jolt comes from the disc wheels—or ‘Moon’ wheels, as Julien calls them. BAAK commissioned them from an American manufacturer, in F19/R16 sizes. They’re fitted with Avon Safety Mileage MKII tires.

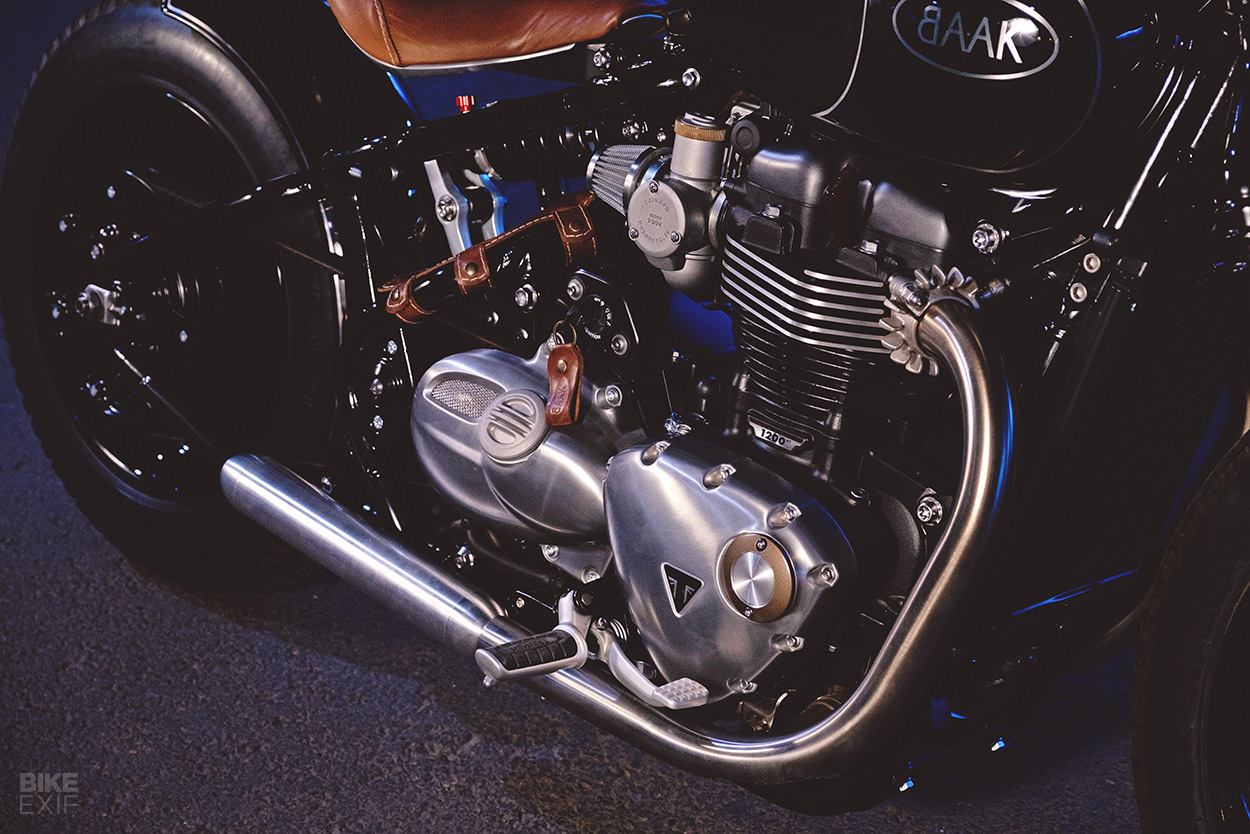

Triumph’s 1200 cc parallel twin is renowned for its grunt, and is tuned exceptionally well. So BAAK have left the mechanicals alone, replaced the airbox system with free-flowing filters, and installed new stainless steel headers and aluminum mufflers. “The customer can decide whether he keeps the original catalytic converter, or goes for an ‘X-pipe’ and removes the cat.”

No injection mapping was required and the renowned grunt of the Bobber engine remains intact. “The injection auto-adjusts,” says Julien. “The setup is even compatible with the X-pipe system.”

Power now hits the back wheel via a low-maintenance belt drive system developed by the Italian company Free Spirits. Installation is relatively simple, aside from having to reposition a bracket.

The wiring was a lot trickier, though—because removing the bulky stock airbox also revealed a lot of the stock loom. So BAAK built a leather cover to hide everything away neatly.

There’s a new speedo (set into a Bates headlight) and switchgear, which required some creative thinking. “We co-designed a plug-n-play electronic box and wiring harness with one of our manufacturing partners,” says Julien.”We can now offer a plug-n-play speedometer solution for all the latest Triumph models.”

“The electronics are really tricky on this motorcycle: it took us months to achieve a functional solution.”

The 1” pullback bars (and custom clamps) are from the BAAK catalog, and are finished with custom aluminum controls and Biltwell grips. “We also deleted the electronic throttle, relocated the system underneath the gas tank, and developed a cable system,” says Julien.

“So we can keep the ‘Ride-By-Wire’ electronic throttle functional, while running a cable throttle inside the handlebars for a cleaner look. These are the kind of details we enjoy spending time on—it really makes a difference.”

Other slick details include compact LED blinkers, a tire-hugging custom rear fender, a luxurious new leather cover for the seat, and a discreet under-bar rear view mirror. Even the license plate holder is neatly integrated into the build.

It’s a supremely well-sorted build, and BAAK’s customer is very satisfied. “Despite the fork and wheels, it remains easy to ride—very stable and agile,” says Julien. “Our customer took it for a test-ride it last Sunday, mostly in the rain, and described it as a very ‘secure’ machine.”

The good news is that a kit is on the way, so Bobber owners will be able to replicate this style. And BAAK will soon be accepting pre-orders from American customers who want a fully built up bike when the store opens next year.

Would you be tempted by the full kit, or are there a few individual parts you’re eyeballing?

BAAK Motocyclettes | Facebook | Instagram

from Bike EXIF https://ift.tt/2zg5hz4

No comments:

Post a Comment