There are many ways to visualize a custom motorcycle before actually putting grinder to metal. Some builders start with a pencil and paper, while others use Photoshop or create 3D renders. But how about building a 1/10th scale model out of stainless steel?

It sounds crazy, but that’s how Jake Drummond conceptualized this show-stopping Yamaha MT-07, dubbed ‘The Omen.’ Jake’s only twenty-five years old, and lives in Oshkosh, Wisconsin—but his whole life has revolved around design and engineering.

His dad is a motorcycle-obsessed pilot who also rebuilds airplanes—so Jake spent countless hours helping out in the hangar as a kid. He built his first custom bike at seventeen, got a job at a kit aircraft manufacturer right out of school, and eventually studied mechanical engineering.

“I was never a good student,” Jake tells us, “and spent most of my time drawing motorcycles, or surfing Bike EXIF for the latest custom goodness.”

From this daydreaming, Jake started developing an idea: a perimeter frame design, with one line running from the steering head to the rear axle. Other considerations included functional rider ergonomics, and materials that would create a natural contrast between the various shapes.

“There was only one option that really caught my eye,” he says, “and that was the Yamaha MT-07. It is light and narrow enough to wrap a frame around, yet it still has plenty of power. It also had an added ‘cool factor,’ because it was the same engine that brought Yamaha back to flat track racing.”

Before buying the donor bike, Jake decided to prototype his idea. And that’s when he started shaping his scale model out of stainless steel.

“It was not the easiest way to prototype something,” he says, “but it turned out really cool and I enjoyed the process.”

Jake had enough to go on before he even completed the scale model. So he put it on pause and started hunting for a wrecked MT-07 to scalp a motor from. Then he got impatient…

“I decided to buy a brand new bike. It was a big commitment for me at the time as a broke college kid, but motorcycles are a disease. They will make you do stupid things whether you are riding them or not.”

“Not long after I got the donor bike I did another stupid thing—I decide to take time off from school to build my dream bike. It was not a decision I took lightly but it felt almost like I didn’t have a choice.”

Jake found a 2016-model MT-07 (previously the ‘FZ-07’ in the US), yanked out the power plant, and got cracking.

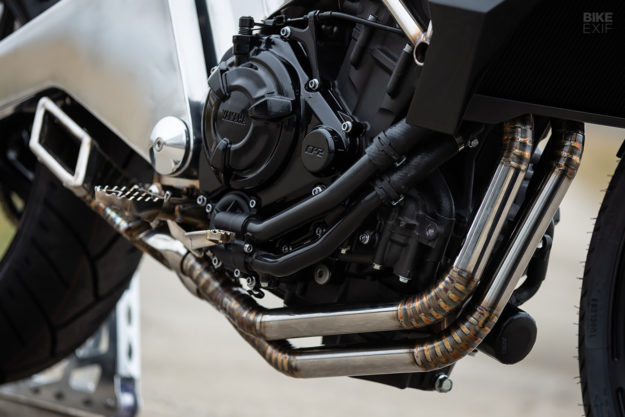

The Yamaha’s 689 cc twin now sits in a hand-shaped, aluminum perimeter frame, that flows down into a custom aluminum swing arm. The engine’s attached to custom-built steel fixings and a forward subframe, and there’s a stainless steel subframe supporting the tail section.

Those air ducts up front are functional; they’re covered by hand-made mesh sections, and also have Yamaha R1 headlights hiding inside them.

Both the fuel tank and the sharp tail piece are hand-shaped aluminum parts. Jake built an integrated tail light out back, with a custom acrylic lens. The radiator side covers and front number plate are his handiwork too.

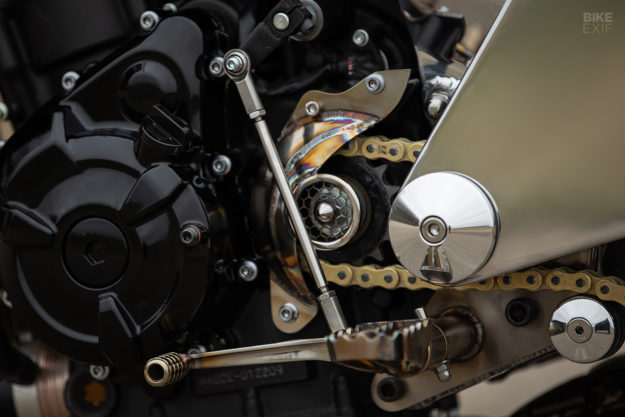

Jake used the Yamaha’s OEM rear shock, but modified the linkage to work with his swing arm. The front forks and triple clamps were lifted from a Yamaha R6. The bike stands rather tall now too, thanks to a set of 21F/18R Morris wheels from Roland Sands Design.

For the cockpit, Jake welded a set of hand-made risers to the polished R6 top triple clamp. He worked in some motocross cues too, with MX-style foot pegs and controls, ProTaper handlebars, and gripper-like pleats on the burgundy leather seat cover.

The brakes are Brembos, upgraded with braided stainless steel hoses. But that’s the end of the off-the-shelf stuff—everything else on this Yamaha was built from scratch.

That includes the brake fluid reservoir, swing arm pivot caps, rear axle adjusters, countershaft cover and a bunch of smaller details.

Oh yes, and that glorious stainless steel exhaust system too—complete with its square, side-exiting muffler.

Jake kept the finishes on his Yamaha basic, but striking. The frame and swing arm are polished, but the rest of the bits were painted in gloss black by Blue Moon Kustoms, with a pearlescent ‘Omen’ logo that Jake designed.

Every last finish was given attention—like the contrasting triangle in the front number board.

The only thing Jake hasn’t managed to finish yet, is The Omen’s final wiring. But when he sent us these killer images of the bike, we simply couldn’t keep them to ourselves.

Who feels like cheering Jake over the finish line with us?

Jake Drummond | Images by Zach Visser | Thanks to our good buddy, P.J. Grakauskas for the tip-off.

from Bike EXIF http://bit.ly/2KJBWSC

No comments:

Post a Comment