In Europe, the Sultans of Sprint competition produces some of the wackiest drag bikes, year on year. It’s written in the rules: contestants vie for gold over an eighth-mile track, but points are also awarded for imagination and creativity.

It means we end up with some very eccentric motorcycles, like this BMW-powered race bike.

‘Achilles’ is entered into the ‘Factory’ class at Sultans of Sprint, and was built as a side project by an engineer and a designer who both work on the car side of BMW. And it’s completely bonkers.

To kick off the project, BMW themselves donated a box fresh R1250RS. We’ve sampled the 1,254 cc boxer motor in the RS and it’s sweet, offering up 136 hp and 143 Nm. It also features BMW’s new ‘ShiftCam’ tech, which is effectively a variable valve timing system that turns the 1250 ballistic at full tilt.

Philipp Ludwig works on bikes under the Kraftstoffschmiede moniker, and he’s a Sultans of Sprint veteran. He’s been racing in the series since its early days, and nabbed a few ‘Freak’ class podiums last year with his heavily modified 1998-model BMW R850R.

But for this project, he called in reinforcements—teaming up with designer Krzysztof Szews from Man & the Machines.

Philipp would do the heavy lifting, with Kris taking point on design. “Designing a piece of motorsport equipment requires industrial design in its purest form,” he says. “There is no need for it to be pretty as long as it performs, right?”

“But this isn’t the case at the Sultans. This race bike had to be an absolute eye catcher: an extrovert, one-off rocket ship, and an ambassador for BMW Motorrad’s sporty brand identity.”

For an engineer, Phil laid some zany ideas on the table. Good weight distribution and straight-line ergonomics were mandatory, but what about a land speeder-style fairing, a hint of bagger flavor, and a 21-inch front wheel?

“Not your usual setup for a sprint bike,” says designer Kris.

Achilles had to be fast and look fast—so Kris started sketching. The design called for a monocoque body that would work in harmony with the boxer motor, and still be aerodynamic. He moved all the visual weight forward to hug that big front wheel, and shortened the tail to give the impression of a lengthened swing arm.

“Not exactly the style Phil had envisioned at the beginning of the project,” says Kris, “but it brought a sparkle to his eye straight away, and he fell in love with the design.”

Wilbers Suspension sent over custom made, fully adjustable front and rear suspension components. The forks are held in place by CNC-machined triples of Phil’s design, with a 50 mm offset for a longer wheelbase and ideal weight distribution. The wheels are custom-built 19F/17R spoked items from Kineo, wrapped in Shinko rubber.

While that was going on, the Kraftstoffschmiede crew stripped the R1250RS down to its bare bones. Phil and his metal shaper, Franz, fabricated a new aluminum fuel cell and tail section. The latter was designed to host the BMW’s engine management system, and a NOS bottle.

Other upgrades include K&N filters, new side air ducts, and a quick release fuel cap. The RS came from BMW with a set of their beautifully machined Option 719 parts; dress-up bits like the engine valve covers and fluid reservoir caps.

The rearsets are custom, placed as far back as possible and lined up for maximum weight transfer to the back wheel (and therefore more traction) off the start line.

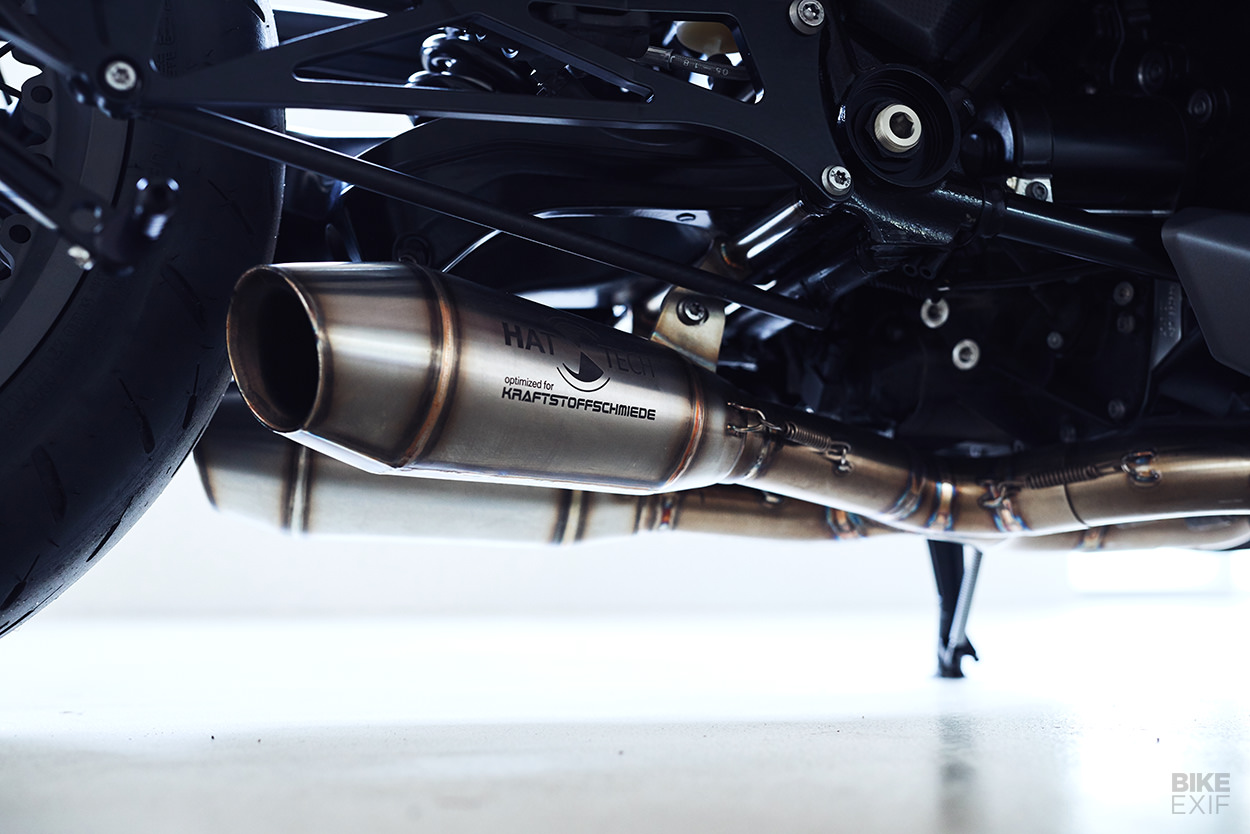

The exhaust system is a custom stainless steel setup from German outfit Hattech, who whipped it up in just a day. But if you’d like more insight into the NOS setup, you’re out of luck: Phil’s lips are sealed on that topic.

Once Phil and Kris agreed on the final design direction—and the rolling chassis was mostly done—the bike was 3D scanned from top to tail. Kris then worked with KKN Engineering, who transferred his design to form-fitted digital renders.

The initial plan was to shape the bodywork with basalt fibers—but that would have blown the budget. So the bodywork was 3D printed from a polyamide material by specialists Creabis. It was produced in multiple sections, which were then joined together and reinforced with carbon fiber in key areas.

On the engineering side, Phil had to contend with the Euro5 standard that the stock R1250RS conforms to. It meant many sleepless nights optimizing the setup on the dyno, and a switch to R1250GS gear ratios.

But it wasn’t without setbacks: in initial tests, the onboard electronics kept freaking out under hard acceleration. Phil finally smoothed out all the kinks, just one day before the first race.

It took Kraftstoffschmiede and Man & the Machines just six months to finish the race bike. “It was a huge challenge,” says Kris. “A complete one-off racing prototype with a perfect finish, built at night while trying to maintain a healthy work/life balance.”

“Phil gave very valuable design input, and learned about industrial design and the motorcycle design process,” says Kris, “while I learned all about race bike requirements and hard business calculations.”

Since the collaboration worked so well, Phil and Kris will be teaming up for more projects, under the banner of Rennstall Moto. Their first build—a K75—is already on the bench, and we can’t wait to see it finished.

Kraftstoffschmiede Instagram | Man & the Machines | Facebook | Instagram | Photos: Philipp Wulk

Sponsors: BMW Motorrad, KKN Engineering, Wilbers Suspension, Hattech Exhausts, Creabis, Ilmberger Carbon Parts and Nitrous Express.

from Bike EXIF http://bit.ly/2ZtaOKf

No comments:

Post a Comment