Volvo has inaugurated their first manufacturing plant in the United States, a new state-of-the-art production facility in Charleston, South Carolina. The plant is central for Volvo’s “Build Where You Sell” strategy, establishing a manufacturing presence in all three of the company’s major sales regions. Volvo says the new South Carolina facility nicely compliments the company’s three European plants – two manufacturing, one engine – plus three factories and an engine plant in China, and assembly plants in India and Malaysia.

“The opening of our first American factory is a very big deal,” said Anders Gustafsson, President and CEO, Volvo Car USA. “Our U.S. business is developing well, our cars have won prestigious awards, and the new South Carolina facility will be a big asset to both Volvo Cars and the community.”

Home Team

Volvo Cars is investing over a billion dollars in the South Carolina plant to create 4,000 new jobs during the coming years. The site includes an office building for up to 300 staff from R&D, purchasing, quality, and sales. Approximately 1,500 will be employed by the end of this year, just as production of the new S60 is beginning. The plant can produce 150,000 cars per year at full capacity.

“The Charleston plant establishes the U.S. as our third home market,” said Håkan Samuelsson, President and Chief Executive, Volvo Cars. “The sedan segment and the SPA platform’s proven ability to boost profitability offer significant growth opportunities for Volvo Cars in the U.S. and globally.”

Environmental Focus

Volvo also wants at least 25 percent of the plastic used in every new model to come via recycled material from 2025 onward. Volvo has already unveiled a specially-built version of the XC60 T8 plug-in hybrid that looks identical to the current model, but has several of its plastic components replaced with recycled materials.

The vehicle’s interior has a tunnel console made from renewable fibres, plastics from discarded fishing nets, and maritime ropes. The carpet contains fibers made from PET plastic bottles and a recycled cotton mix from clothing manufacturers’ off-cuts. The seats also use PET fibers from plastic bottles; seats from old Volvo cars were even re-purposed for sound-absorbing material.

“Environmental care is one of Volvo’s core values and we will continue to find new ways to bring this into our business,” Samuelsson said. “This car and our recycled plastics ambition are further examples of that commitment.”

Collaborative Effort

Volvo is urging suppliers to work closely with automakers to develop a more sustainable approach to manufacturing.

“We already work with some great, forward-thinking suppliers when it comes to sustainability,” explained Martina Buchhauser, Senior Vice President of Global Procurement, Volvo Cars. “However, we do need increased availability of recycled plastics if we are to make our ambition a reality.”

Volvo is also pushing for climate-neutral operations by 2025, and in January, the engine plant in Skövde, Sweden became the company’s first such facility.

“That is why we call on even more suppliers and new partners to join us in investing in recycled plastics and to help us realize our ambition,” Buchhauser added.

The Automoblog Staff contributed to this report and can be reached anytime.

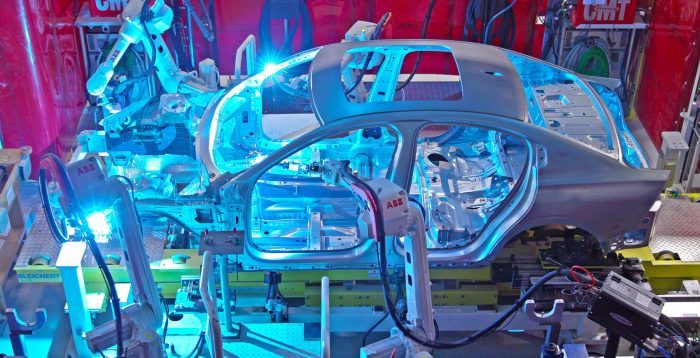

Volvo’s South Carolina Plant Gallery

Photos & Source: Volvo Car Group.

from Automoblog.net https://ift.tt/2K7mlYn

No comments:

Post a Comment